服務熱線:

<ul id="8iguc"></ul> <del id="8iguc"></del> <strike id="8iguc"></strike>

服務熱線:

傳真:0769-2289 9811

手機:18925574911

郵箱:market@leelool.com網址:www.tjhzyb.com

地址:廣東省東莞市松山湖園區新竹路7號1棟102室

綠聯凈化Leelool黑煙凈化器旁通系統

Leelool DPF Bypass System

前言

在黑煙凈化器中,旁通系統承擔著開/閉旁通管路從而控制廢氣流向的作用。黑煙凈化器正常工作時,旁通系統關閉,發動機尾氣通過凈化器處理后排出。黑煙凈化器對啟動黑煙處理完成后,旁通系統自動打開,發動機尾氣通過旁通管道直接排出。

In DPF, the bypass system plays a role in opening or closing the bypass pipeline to control the flow of exhaust gas.When DPF is working normally, the bypass system is closed and the engine exhaust is purified by the purifier before being discharged.After the DPF completes the exhaust treatment during startup, the bypass system opens and the engine exhaust is directly discharged through the bypass pipe.

旁通系統不僅是確保黑煙凈化器正常運行的核心部件,更是確保發動機運行和操作人員人身的關鍵因素。因此,在黑煙凈化器的選擇、安裝和維護中,整個旁通系統的性能和可靠性尤為重要。

The bypass system is not only the core component for the normal operation of the exhaust purifier,but also a key factor in ensuring the safe operation of the engine and the personal safety of the operators.Therefore,in the selection, installation,and maintenance of exhaust purifiers,the performance and reliability of bypass system are particularly important.

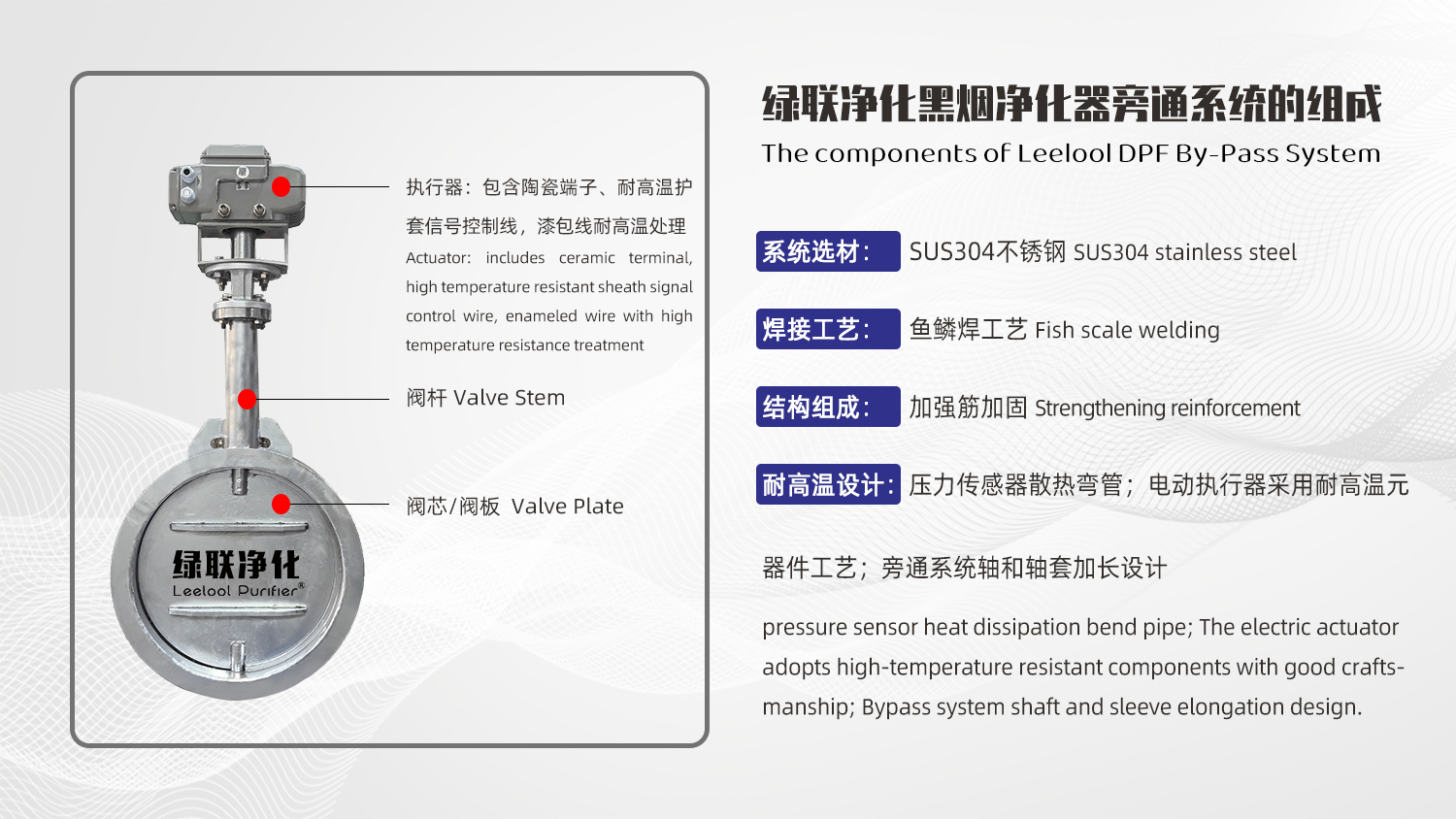

旁通機構的組成

①旁通機構(閥體,閥芯/閥板,閥桿,執行器:陶瓷端子、耐高溫護套信號控制線,漆包線耐高溫處理);②旁通管(等于凈化器進/出口煙管直徑);③壓力信號采集及傳輸:壓力傳感器要安裝散熱管+散熱翅片;④控制系統:電控箱、控制模塊、繼電器、指示燈、按鈕及控制線路。作用是凈化器工作狀態顯示,采集的信號處理,輸出信號給旁通系統進行開/閉。

①Bypass mechanism (valve body, valve core and valve plate, valve stem, actuator: ceramic terminal, high temperature resistant sheath signal control wire, enameled wire with high temperature resistance treatment).②Bypass pipe (equal to the diameter of the inlet or outlet smoke pipes of the purifier).③Pressure signal acquisition and transmission: The pressure sensor should be equipped with a heat pipe and heat dissipation fins.④Control system: electrical control box, control module, relay, indicator light, button and control circuit. The function is to display the working status of the purifier, process the collected signals, and output signals to the bypass system for opening or closing.

旁通系統性能的影響因素

1. 系統的選材

Material selection

2. 系統的焊接工藝

Welding process

3. 系統的結構組成

Structural composition

4. 耐高溫電動執行器

High temperature resistant electric actuator

5.控制系統:背壓信號采集傳感器及信號輸送線路

Control system: Back pressure signal acquisition sensor and signal transmission line

本期看點

綠聯凈化黑煙凈化器旁通系統特點

PART.1

旁通系統裝配過程

Bypass syetem assembly process

1.1壓蓋安裝Install cover

連接和固定旁通系統中心軸點,增加密封性

Connect and fix bypass system to increase sealing performance

1.2支架安裝Install bracket

保證旁通系統軸心點位于中線

Ensure bypass system axis point is located at the centerline

1.3旁通系統軸和軸套安裝/聯軸器安裝

Install bypass system shaft and sleeve/Install coupling

1.4墊片安裝Install gasket

平衡基座的同時隔絕與執行器間的熱度

Balance the base while isolating heat

1.5電動執行器安裝Install electric actuator

PART.2

旁通系統與電控箱聯動調試

Linkage debugging

2.1電控箱初始參數設定Set initial parameters

聯動電控箱,調節背壓數值

Linkage control box and adjust back pressure value

2.2壓力傳感器測試Pressure sensor testing

手動模式下測試系統打開的功能(X6倍速)

Test the function of system opening in manual mode

手動模式下測試系統關閉的功能(X6倍速)

Test the function of system closing in manual mode

2.3模擬運行工況調試Simulate debugging

模擬超壓工況,記錄報警時間(X5倍速)

Simulate overpressure conditions and record alarm time

PART.3

手動開閉旁通系統的方法演示

Manual opening and closing bypass system

3.1.手動打開系統操作方法演示

Demo of manual system opening operation method

使用內六角螺栓插入手動搖桿位置,逆時針旋轉,約150圈

Insert the hexagonal socket bolt into the manual joystick and rotate counterclockwise for about 150 turns

系統逐漸打開(X3倍速)The system gradually opens

3.2.手動關閉系統操作方法演示

Demo of manual system closing operation method

使用內六角螺栓插入手動搖桿位置,順時針旋轉,約150圈

Insert the hexagonal socket bolt into the manual joystick and rotate it clockwise for about 150 turns

系統逐漸關閉(X3倍速)The system gradually opens

本期小結

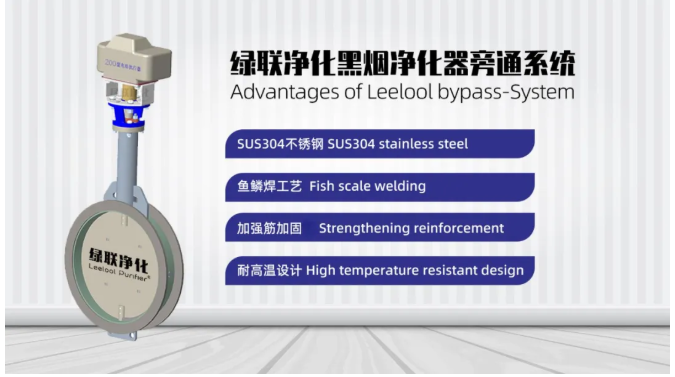

綠聯凈化黑煙凈化器旁通系統特點

Advantages of Leelool bypass-system

系統選材:SUS304(厚度≥10mm)SUS304(Thickness ≥ 10mm)

焊接工藝:魚鱗焊工藝Fish scale welding

結構組成:加強筋加固Strengthening reinforcement

耐高溫設計:壓力傳感器散熱彎管;電動執行器采用耐高溫元器件工藝;旁通系統軸和軸套加長設計

High temperature resistant design: pressure sensor heat dissipation bend pipe; The electric actuator adopts high-temperature resistant components with good craftsmanship; Bypass system shaft and sleeve elongation design